In many engineering applications, power is required to transmit from one point to another. Various power transmission systems such as electrical, mechanical, hydraulic, pneumatic, etc. can fulfill different requirements. Mechanical power transmission systems are used to transmit power, motion and torque from driver shaft (a prime mover such as electrical motor) to the driven shaft. Changing direction, speed and intensity are also important tasks for such transmission systems. There exist several drives to transmit a wide range of torque or power in various distances and subsequently modify them as per requirement. Gear drive and belt drive are two prominent mechanical power transmission systems overwhelmingly used in machineries and industries. Apart from these two drives, chain drive, rope drive, coupling, etc. are also examples of mechanical power transmission system.

In case of gear drive, power and motion are transferred from one shaft to another shaft through successive engagement and disengagement of teeth of two mating gears. Teeth are cut on both the gears and one such gear is mounted on driving shaft while other gear is mounted on the driven shaft. There is no requirement of ancillary element other than two mating gears. Gear drive is especially suitable from small distance but heavy power transmission. Contrary to this, chain drive is suitable for comparatively long distance power transmission requirements; however, load carrying capacity of chain drive is comparatively small. In chain drive, sprocket is mounted on each of the driving and driven shafts while an endless chain connects the sprockets. It is also engagement type drive, but it can inherently absorb vibrations induced in machine unit. Various similarities and differences between gear drive and chain drive are given below in table format.

Similarities between gear drive and chain drive

- Both gear drive and chain drive are engagement type mechanical drives. Mechanical drives can be either engagement type of friction type (like belt drive or rope drive). In engagement drives, two elements engage and disengage successively for power transmission; while in friction drives, power transmission occurs only due to frictional force acting between two elements.

- Both are positive drives as no slip occurs during operation. So they offer constant velocity ratio. However, chain drive sometimes fails to provide constant velocity ratio, especially during prolonged usage of chain (chain may stretch).

- Both are suitable for small to medium distance power transmission requirements. For long distance (>1m), belt drive is preferred.

- Both the drives require proper lubrication for prolonged service.

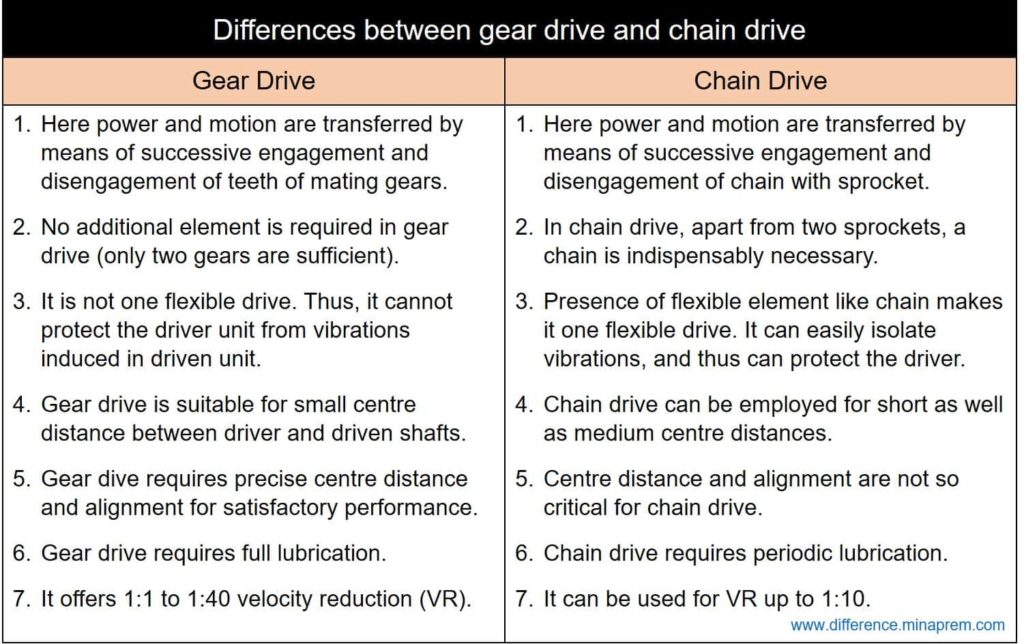

Differences between gear drive and chain drive

| Gear Drive | Chain Drive |

|---|---|

| Gear drive is one engagement type mechanical drive as power and motion are transferred by means of successive engagement and disengagement of teeth of mating gears. | Chain drive is also one engagement type mechanical drive but power and motion are transferred by means of successive engagement and disengagement of chain with sprocket. |

| No additional element is required in gear drive (only two gears are sufficient for power transmission). | In chain drive, apart from two sprockets, a chain is indispensably necessary for power transmission. |

| It is not one flexible drive. Thus, it cannot protect the driver unit from vibrations induced in driven unit. | Presence of flexible element like chain makes it one flexible drive. It can easily isolate vibrations, and thus can protect the driver. |

| Gear drive is suitable for small centre distance between driver and driven shafts. | Chain drive can be employed for short as well as medium centre distances between driver and driven shafts. |

| For the same centre distance, gear drive requires more space. The drive unit is also heavy. | Chain drive is compact and thus space efficient. Drive unit is light in weight. |

| Gear dive requires precise centre distance otherwise performance will degrade sharply. | Centre distance is not so critical for chain drive. A small error is tolerable without much effect. |

| Gear drive requires full lubrication. For best performance and longer life in heavy duty applications, gears must be partially immersed into lubricating oil. | Chain drive also requires lubrication to reduce noise and wear of joints; however, it does not require full lubrication (periodic lubrication is sufficient). |

| Gear drive can be utilized for parallel (spur and helical gears), intersecting (bevel gear), and non-intersecting non-coplanar (worm gear) shafts. | Chain drive is suitable for parallel shafts only. |

| Operation of gear drive is quiet. | Operation of chain drive is noisy. |

| A wide range of velocity reduction (1:1 to 1:40) is possible with gear drive. | Chain drive is not suitable for high velocity reduction. It can be used when reduction is up to 1:10. |

References

- Introduction to Machine Design by V. B. Bhandari (McGraw Hill Education India Private Limited).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand).

- Theory of Machines by R. S. Khurmi and J. K. Gupta (S. Chand).