Every engineering material, when in service, is subjected to external loading of several natures (continuous, repetitive or fluctuating loading). In some applications (for example, metal rolling or bending), it is intended that the component should elongate as much as possible before fracture; while in other applications (for example, stone braking), it is intended that the material should break with minor deformation under external loading. Based on the capability to elongate under external loading, solid materials can be classified in two categories – ductile and brittle.

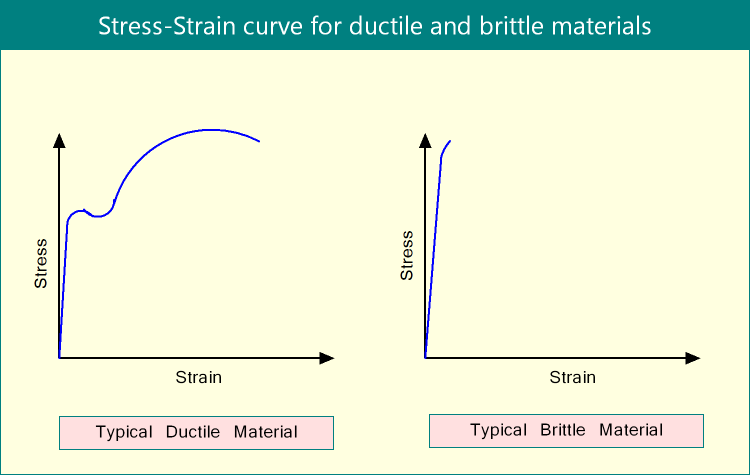

When external tensile load is applied on a material, initially it undergoes elastic deformation and then plastic deformation starts. An elastic deformation is recoverable, while a plastic deformation is permanent. Ability of a material to plastically deform to a larger extent under external loading is called docility; while brittleness is the measure of tendency of a material to undergo negligible plastic deformation before fracture. Materials that show substantial plastic deformation under external loading are called ductile materials; while brittle materials exhibit negligible plastic deformation. Similarities and differences between ductility and brittleness are provided below.

Similarities between ductility and brittleness

- Both are associated with the plastic deformation of the material under tensile loading.

- Ductility or brittleness is highly temperature dependent. For example, a brittle material can behave like a ductile one at an elevated temperature. Similarly a ductile material at room temperature, when frozen, can automatically convert into brittle material.

- Ductility or brittleness of a material also depends on the inbuilt stress level. Under presence of high residual stress, a ductile material may fail without palpable plastic elongation.

Differences between ductility and brittleness

| Ductility | Brittleness |

|---|---|

| Ductility is defined as the ability of solid material to plastically deform to a larger extent before fracture when it is subjected to external tensile loading. | Brittleness is defined as the tendency of solid material to undergo negligible plastic deformation before fracture when it is subjected to external tensile loading. |

| Solid material having high ductility is called Ductile Material. | Solid material that shows brittleness is called Brittle Material. |

| Percentage elongation of the ductile materials before fracture under tensile testing is higher. | Percentage elongation of the brittle materials before fracture under tensile testing is very less. |

| Ductile materials fail gradually by neck formation under the action of external tensile loading. | Brittle materials fail by sudden fracture (without any warning such as necking). |

| Energy absorbed by ductile materials before fracture under tensile testing is more. | Brittle materials absorb very small energy before fracture. |

| Various metal forming operations (such as rolling, forging, drawing, bending, etc.) can be performed on ductile materials. | Forming operations cannot be easily performed on brittle materials. For example, brittle material cannot be drawn into wire. |

| Ductile materials show longer life when subjected to fatigue loading. | Brittle materials fail faster when subjected to fatigue loading. |

Examples of ductile material:

|

Examples of brittle material:

|

References

- Book: Mechanics of Materials by F. P. Beer, E. R. Johnston and J. T. Dewolf (Tata McGraw-Hill Education). Buy this book

- Book: Callister’s Materials Science and Engineering by R. Balasubramaniam (Wiley India). Buy this book