Non-traditional machining (NTM) processes can directly employ various forms of energy for removing material from workpiece in order to fabricate the intended 3-D feature. EDM, LBM, EBM, and PAM are four common NTM processes that use thermal energy (heat) to selectively remove material. In these processes, material removal mostly takes place in vaporized and sometimes in molten state. The source of heat is, however, different for these four processes. Laser Beam Machining (LBM) is one thermal energy based NTM process where material is removed by melting and vaporization through the action of a high energy density laser beam. First, a monochromatic and coherent beam of laser (Light Amplification by Stimulated Emission of Radiation) is generated using suitable lasing medium (Nd-YAG, Nd-Glass, Ruby, CO2). The beam is then constricted to increase energy density, and the constricted laser beam is focused on the working surface with the help of lenses. Intense heat generation occurs at a very narrow spot where the laser beam strikes the workpiece surface leading to an instantaneous localized temperature rise of the order of 10,000°C. Such a high temperature can rapidly melt down and vaporize any solid material. Accordingly, majority of the material removal occurs in vapour state. The workpiece is usually integrated with the CNC system to move the worktable at a specified path at pre-set feed rate for cutting a particular profile.

Plasma is an extremely hot matter consisting of ionic particles. Plasma Arc Machining (PAM), also known as Plasma Arc Cutting (PAC), utilizes a high velocity jet of plasma to supply thermal energy (heat) for melting and vaporizing the workpiece. In order to artificially generate plasma, a suitable plasma forming gas (such as air, argon, nitrogen, and hydrogen) is first introduced into a gas chamber under high pressure. An electric arc is also constituted between a tungsten electrode and copper nozzle of the chamber (or workpiece, if it is conductive). The plasma forming gas is then forced to pass surrounding the electric arc through the small nozzle opening. Owing to the intense arc heating, the gas gets converted to high temperature plasma. This plasma jet is then directed towards the workpiece, where it rapidly elevates the cutting zone temperature to as high as 20,000°C leading to melting and vaporization. Although a fraction of the workpiece material is removed in vaporized form, rest of the material in molten state is blown away from the cutting zone by the high velocity plasma jet. Thus, material removal in PAM is a combination of (i) displacing the molten metal and (ii) vaporizing the material. Plasma jet is relatively wider, and thus the process is associated with broader heat affected zone and wider kerf. PAM is not suitable for precise and miniaturized feature fabrication. Rather it is preferred for thick cutting or plasma heating regardless of the mechanical, electrical and chemical properties of the sample. Various similarities and differences between LBM and PAM are given below in table format.

Similarities between LBM and PAM

- Both the LBM and PAM processes are thermal energy based non-traditional machining (NTM) processes as material removal takes place by melting and vaporization of workpiece materials. However, the source of heat is different for these two processes.

- No vacuum chamber is required for operation of LBM or PAM process. This is unlike EBM and IBM (FIB) where the work chamber must have low vacuum pressure.

- Both the processes can be applied for electrically conductive as well as non-conductive materials. Electrical conductivity plays no role on the performance and applicability of these two processes. However, the arcing fashion in PAM is different for electrically conductive and non-conductive materials.

- Both the LBM and PAM processes can create thermal damages to the workpiece. A narrow heat-affected zone (HAZ) exists on the processed samples. However, this HAZ is usually wider for PAM as compared to that for LBM.

- In both the processes, several parameters and various movements are usually controlled by CNC system.

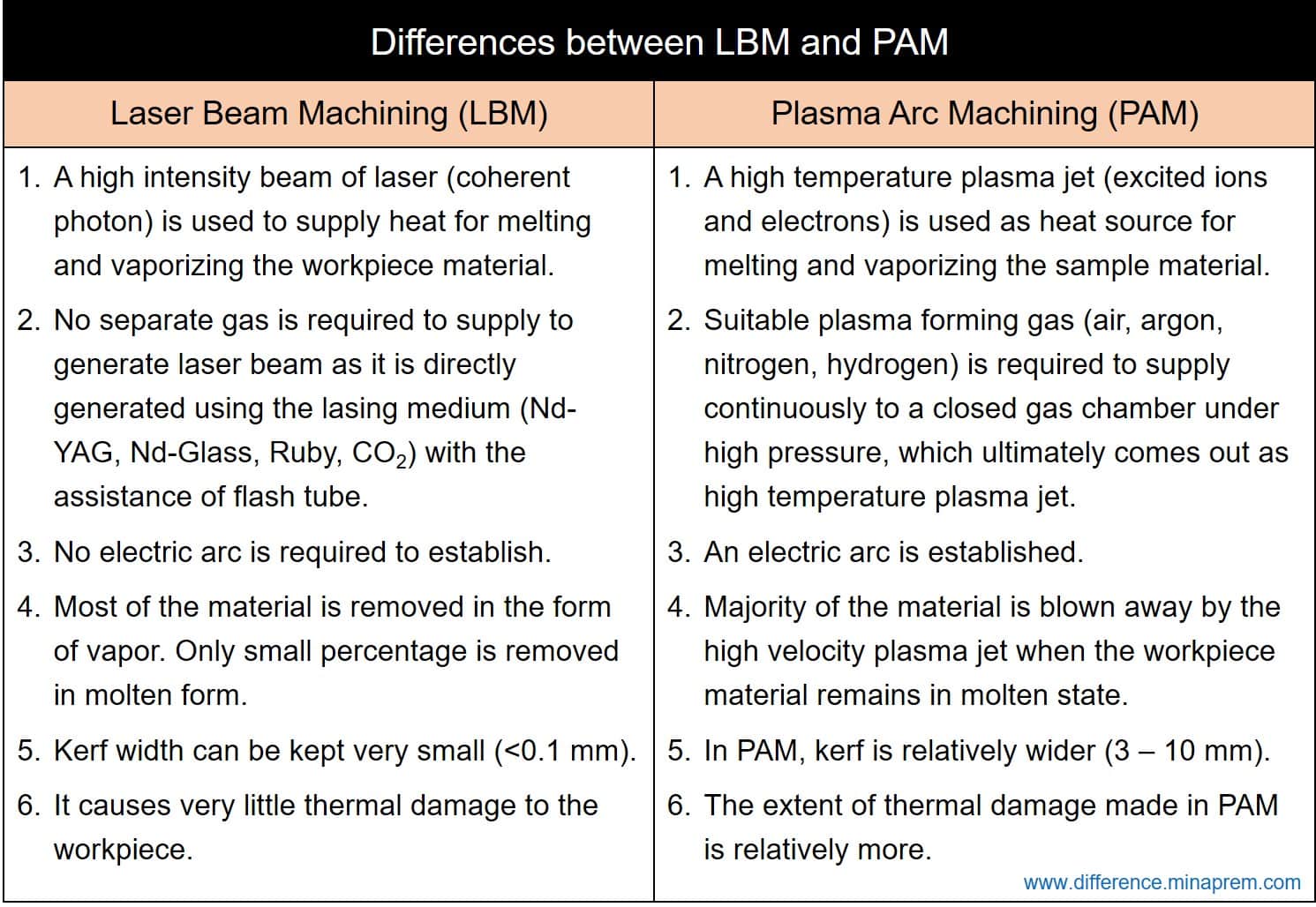

Differences between LBM and PAM

| Laser Beam Machining (LBM) | Plasma Arc Machining (PAM) |

|---|---|

| A high intensity beam of laser (coherent photon particles) is used to supply heat for melting and vaporizing the workpiece material. | A high temperature plasma jet (highly excited ions and electrons) is used as the heat source for melting and vaporizing the workpiece material. |

| No separate gas is required to supply to generate laser beam as it is directly generated using the lasing medium (Nd-YAG, Nd-Glass, Ruby, CO2) with the assistance of flash tube. | Suitable plasma forming gas (air, argon, nitrogen, hydrogen) is required to supply continuously to a closed gas chamber under high pressure, which ultimately comes out as high temperature plasma jet. |

| No electric arc is required to establish in LBM process. | An electric arc is essentially required to supply immense heat for converting the gas into plasma. This arc can be constituted between (i) a tungsten electrode and (ii) nozzle or workpiece. |

| Although melting and vaporization both occur simultaneously, most of the material is removed in the form of vapour. Only small percentage is removed in molten form. | Both melting and vaporization occur in PAM too; however, majority of the material is blown away by the high velocity plasma jet when the workpiece material remains in molten state. A comparatively smaller fraction of the material is removed in vaporized form. |

| The laser beam characteristics (such as beam diameter, energy density, incidence timing, incidence pattern, etc.) can be controlled effectively and easily. Such parameters can also be changed rapidly as per the desired level. | PAM is less flexible in terms of parameter controlling and their variation. |

| Laser beam can be allowed to strike the workpiece either continuously or intermittently (as in the case of femtosecond laser). | Plasma jet is usually allowed to continuously strike the workpiece. |

| In LBM, the kerf width can be maintained very small (even below 0.1 mm). | In PAM, kerf is relatively wider (3 – 10 mm). |

| A narrow localized heat-affected zone can be noticed in the specimens after cutting by LBM. So it causes very little thermal damage to the workpiece. | Specimens cut by PAM can have significantly wider heat-affected zone. The extent of thermal damage made in PAM is more. |

| LBM process capability is affected by optical properties of the workpiece surface (transparent, translucent and opaque). Highly reflective surface can reduce rate of heat input. | PAM process is not affected by the optical properties of the workpiece surface. |

| LBM process is not noisy and can be carried out without specific personal protections. | PAM process is very noisy. Thus proper hearing protection (like ear muffler) is needed for operators. |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).