Non-traditional machining (NTM) processes can directly utilize different forms of energy (like mechanical, thermal, chemical, electric, light, etc.) to selectively remove material from the workpiece in order to fabricate intended 3-D feature. These processes eliminate the barrier imposed by mechanical strength and hardness of the workpiece for processing by a conventional metal cutting process. Several NTM processes have emerged over the last few decades, which include AJM, USM, CHM, ECM, LBM, PAM, EBM, IBM, etc. Each of these processes has distinct capability in terms of processable materials, feature size, achievable accuracy, extent of collateral damage, etc. Electron Beam Machining (EBM) is one thermal energy based NTM process where a concentrated beam of high velocity electrons is used to remove material by melting and vaporization. First ample free electrons are generated in a tungsten cathode, and these electrons are then accelerated in an electric field by means of high potential difference. Several lenses are used to constrict the high velocity electrons in the form of a narrow beam. This electron beam is allowed to strike the workpiece where the kinetic energy of the electrons is converted into thermal energy leading to immense heat generation. Localized temperature rise can be as high as 10,000°C, which can melt down and vaporize the workpiece material leading to material removal. The entire EBM process is carried out in a high vacuum (1 × 10-8 atm) chamber (i) to avoid excessive collisions between the electrons and air molecules, and (ii) to protect tungsten filament from oxidation.

On the other hand, Ion Beam Machining (IBM) utilizes a concentrated beam of high velocity ions to remove material. However, material removal in IBM does not take place by melting and vaporization. Rather, the high velocity ions strike the molecules of the workpiece surface and knock them out by means of momentum transfer. The associated mechanism of material removal is termed as “sputtering” where incidental ions strike a solid surface to dislodge one or more atoms from the surface leading to material removal in atomic level. Sometimes assistance of a gaseous medium is also taken for efficient knocking of the surface atoms. Owing to atomic removal, the material removal rate in IBM is very low; however, it can produce highly finished surface. Moreover, ions don’t generate excessive heat on the workpiece surface, and thus extent of thermal damage is also negligible. Though IBM process is carried out in a soft vacuum chamber, it does not require very low pressure to be maintained as it is required in EBM. A variant of IBM process, focused ion beam (FIB) is gaining popularity in micro- and nano-fabrication domains owing to its inherent capability of manipulating atoms. Various similarities and differences between EBM and IBM processes are given below in table format.

Similarities between EBM and IBM

- Both electron beam and ion beam machining processes are categorized as non-traditional machining (NTM) processes or advanced machining processes (AMP). However, the mechanism of material removal in EBM and IBM is different.

- Both follow the subtractive manufacturing approach (material is removed gradually from a solid block) for fabricating intended 3-D feature.

- Capability of these two processes does not depend on mechanical strength or hardness of the sample material. Chemical properties of the workpiece also have no influence on these two processes. However, IBM process relies on surface binding energy of the workpiece.

- In none of these two processes, physical contact between the tool and workpiece exits. In fact, no such solid tool is employed in these processes. Thus these processes are free from burr formation, gradual tool wear, mechanical residual stress, etc. It is worth mentioning that residual stress may develop owing to thermal cycle in EBM.

- Both are suitable for small components as the process must be carried out in a vacuum chamber with controlled environment.

- These processes are commonly integrated with computer control system to facilitate precise control.

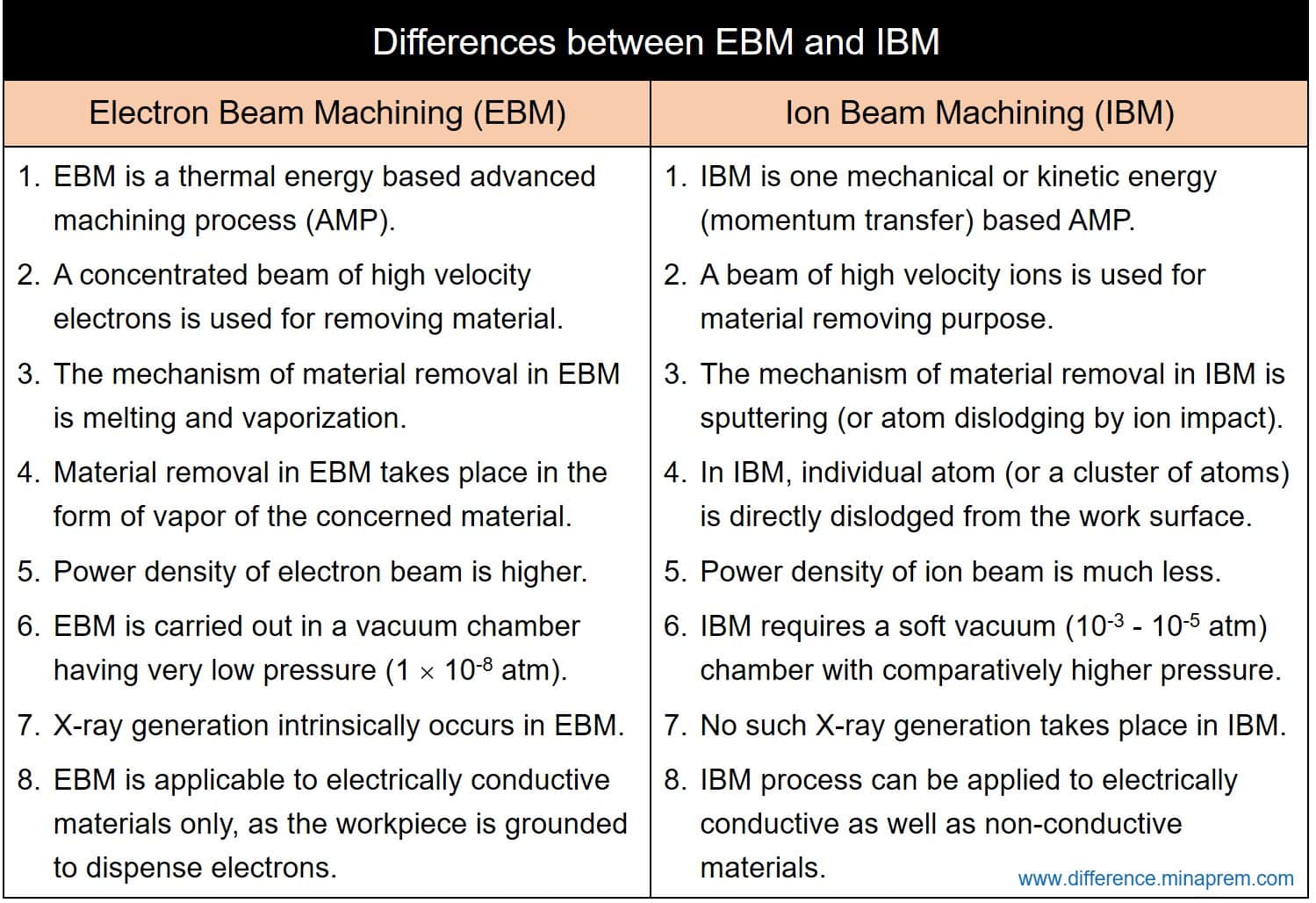

Differences between EBM and IBM

| Electron Beam Machining (EBM) | Ion Beam Machining (IBM) |

|---|---|

| EBM is a thermal energy based advanced machining process. | IBM is one mechanical or kinetic energy (momentum transfer) based advanced machining process. |

| A concentrated beam of high velocity electrons is used to supply heat for removing material from workpiece. | A beam of high velocity ions is used for material removal purpose. |

| The mechanism of material removal in EBM is melting and vaporization. | The mechanism of material removal in IBM is sputtering (or atom dislodging by ion impact). |

| Material removal in EBM takes place in the form of vapour of the concerned workpiece material. However, small fraction of material is removed in molten form. | In IBM, individual atom (or a cluster of atoms) is directly dislodged from the workpiece surface. Continuous dislodging is required to realize sizeable amount of material removal. However, no melting or vaporization takes place. |

| Power density of the electron beam is relatively higher (103 to 106 W/mm2). | Power density of ion beam is significantly less (10-2 to 100 W/mm2). |

| EBM process is carried out in a vacuum chamber having very low pressure (1 × 10-8 atm) to avoid collision of electrons with air molecules and to protect hot tungsten filament. | IBM process requires a soft vacuum chamber with comparatively higher pressure, in the order of 10-3 to 10-5 atm. |

| X-ray generation intrinsically occurs in EBM process. Thus, the process is somewhat risky to the operator. | No such X-ray generation takes place in IBM process. So, it is relatively safer to operate. |

| EBM process is applicable to electrically conductive materials only, as the workpiece is grounded (earthen) to dispense electrons for maintaining electrical neutrality. (The electron beam strikes the workpiece to generate thermal energy. These electrons must be continuously dispensed from workpiece to avoid accident and reduce repulsion force to the incident beam). | IBM process can be applied to electrically conductive as well as non-conductive materials. |

| EBM process capability depends on the thermal properties (such as conductivity, diffusivity, etc.) of the workpiece material. | IBM process is mostly independent of the thermal properties of the workpiece material. |

| It can cut features having high aspect ratio (up to 5:1). Deep hole drilling and thick cutting (up to 6 mm thickness) can be carried out using EBM. | It is not suitable for deep cutting or fabricating features having high aspect ratio. IBM is preferred for shallow contouring, micro-cutting, polishing, etc. |

| The width or area of thermal damage observed in EBM process is relatively wider. | Impact damage on the workpiece is very narrow in IBM process. Often, no palpable collateral damage is perceived. |

| Material removal rate (MRR) of EBM process is significantly higher (around 40 mm3/min). So it is a productive and economic process. | Material removal rate (MRR) of IBM process is very low (in the order of 2 × 10-4 mm3/min). |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Allen et al. (2009). Ion beam, focused ion beam, and plasma discharge machining. CIRP Annals. https://doi.org/10.1016/j.cirp.2009.09.007