Mechanical energy based non-traditional machining (NTM) processes directly utilize mechanical energy to gradually remove material from the workpiece primarily by erosion. Examples of such processes include abrasive jet machining (AJM), water jet machining (WJM), abrasive water jet machining (AWJM) and ultrasonic machining (USM). In abrasive jet machining, abrasive particles are first mixed with the compressed gas at a pre-defined mixing ratio. This mixture is then directed towards the workpiece in the form of a high velocity jet by means of a nozzle. The small diameter nozzle converts the pressure energy of the air-abrasive mixture into kinetic energy, and thus high velocity jet is obtained. This nozzle also maintains appropriate stand-off distance (SOD) and discharge angle. This high velocity jet erodes material from the work surface at a controlled rate and thus material removal is obtained. Here only abrasive particles participate in erosion of workpiece material; compressed air has no role in it.

In water jet machining (WJM), a high velocity jet of water is used to remove material. Here a fluid pump is used to enormously increase water pressure (as high as 2500 – 4000 bar). This pressurized water is then discharged with the help of small diameter nozzle that converts the pressure energy into kinetic energy. The water jet that comes out of the nozzle possesses enough energy to slice polymeric or organic materials. Thus WJM is commonly used in food, polymer and leather industries. Often stabilisers (mainly long chain polymers) are mixed with water to reduce the tendency of jet flaring once it is discharged from nozzle. Sometimes smaller size solid abrasive particles are also mixed with the water to improve cutting ability. Such a process where abrasives are mixed with water is termed as Abrasive Water Jet Machining (AWJM). It can efficiently cut thin metallic sheets apart from polymer, wood and leather. However, presence of abrasive makes this process unsuitable for food slicing. Although, AJM and WJM both employ high velocity jet to cut material, they are different in several aspects. Various similarities and differences between AJM and WJM are given below in table format.

Similarities between AJM and WJM

- AJM and WJM both are non-traditional machining processes (NTM). However, none of them is considered as hybrid process. A hybrid NTM process is a combination of two processes where workpiece material is removed simultaneously in two distinct ways.

- Both are mechanical energy based NTM processes as they directly utilize kinetic energy to remove material. Abrasive water jet machining (AWJM) and ultrasonic machining (USM) also expand mechanical energy for material removal. There are several other NTM processes that expand other forms of energy for material removal (such as thermal energy in LBM, PAM and EBM, electro-chemical energy in ECM, etc.).

- Both the processes require an appropriate nozzle for converting pressure energy of fluid (air in case of AJM, water in case of WJM) into kinetic energy (in the form of high velocity jet).

- Performance of AJM or WJM does not depend on electrical and thermal conductivity and chemical inertness of the workpiece material. However, several mechanical properties like strength, hardness, etc. influence process capability.

- None of these processes is associated with the burr formation, thermal damages, etc.

- Both the processes can be integrated with CNC system for efficient control and precise delivery of jet. It also helps reducing environmental pollution and at the same time it offers a healthy working condition for workers.

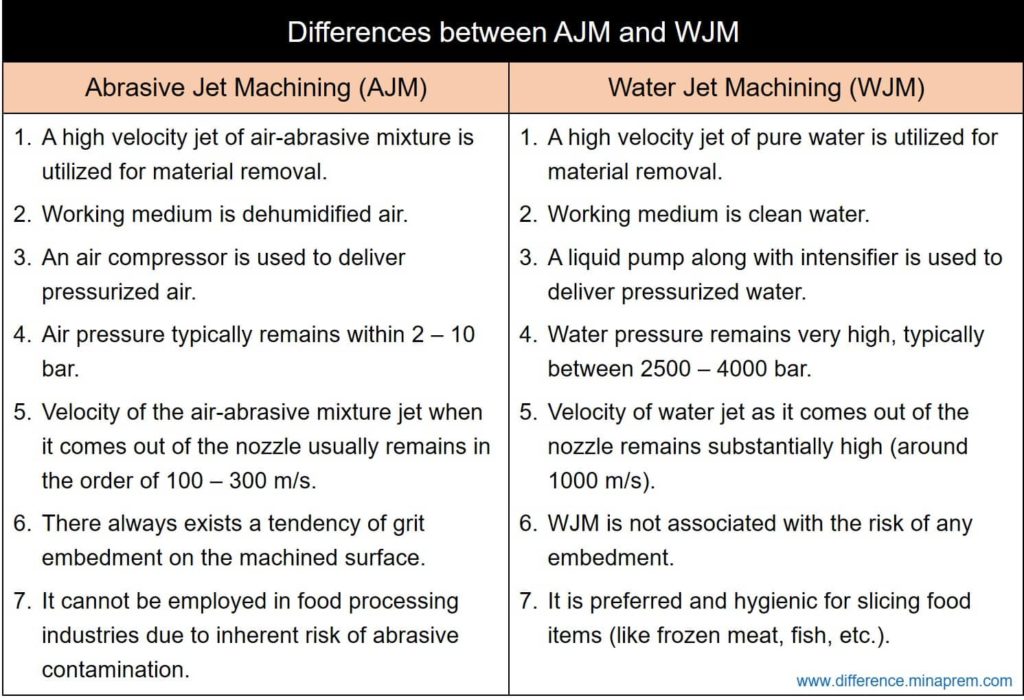

Differences between AJM and WJM

| Abrasive Jet Machining (AJM) | Water Jet Machining (WJM) |

|---|---|

| A high velocity jet of air-abrasive mixture is utilized for material removal. | A high velocity jet of pure water is utilized for material removal. |

| The working medium for AJM is dust-free and dehumidified air. | Working medium in WJM is clean water. |

| An air compressor is used to deliver pressurized air. | In place of air compressor, a liquid pump along with intensifier is used to deliver pressurized water. |

| Air pressure typically remains within 2 – 10 bar. | Water pressure remains very high, typically between 2500 – 4000 bar. |

| Velocity of the air-abrasive mixture jet when it comes out of the nozzle usually remains in the order of 100 – 300 m/s. | Velocity of water jet as it comes out of the nozzle remains around 1000 m/s. |

| There always exists a tendency of grit embedment on the machined surface in AJM. This may affect surface properties and appearance. | WJM is not associated with the risk of any embedment (as no abrasive is utilized here). |

| It cannot be employed in food processing industries due to inherent risk of abrasive contamination. | It is preferred and hygienic for slicing food items (like frozen meat, fish, etc.). |

| It can efficiently machine hard materials including metals. In fact, AJM is preferred for machining hard brittle metals and ceramics. | Water jet does not possess enough power for cutting metals or ceramics. It is suitable for cutting softer materials like woods, rubber, leather, etc. |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).