Machining is basically one material removal process where excess material is sheared off by the mutual interaction between workpiece and cutting tool. There exist several machining processes to cater the need of processing a wide variety of workpiece materials in innumerable ways. For examples, lathe operations (such as straight turning, taper turning, internal turning, threading, grooving, etc.) are primarily carried out to generate cylindrical or conical surfaces. Milling operations are carried out primarily for generating flat surfaces. Similar to the lathe and milling operations, shaping and planing are two machining processes that can generate flat surfaces at different planes or orientations. However, the rotation of workpiece or cutting tool imparts necessary cutting velocity the lathe operations and milling processes. On the contrary, both shaping and planing processes utilize only reciprocating motion to provide three necessary process parameters (cutting velocity, feed motion, and depth of cut).

Since reciprocating motion is utilized to impart cutting velocity both in shaping and planing, so either the cutting tool or the workpiece is required to reciprocate. Here, only forward stroke is utilized for removing material, while the backward stroke is kept idle. So cutter engages with the workpiece only in forward stroke. Since backward stroke does not involve in cutting, so the time of this redundant stroke can be reduced while giving more time for forward stroke. Quick-return mechanism is commonly employed to for this purpose. Although both shaping and planing utilize quick-return mechanism, their main difference lies on the point of application of cutting velocity. In shaping, the reciprocating movement of the tool provides cutting velocity; while in planing reciprocating movement of work table (workpiece) provides intended cutting velocity. Accordingly, quick-return mechanism is integrated with the cutter for shaping operation and with the worktable in planing operation. Although there are many similarities among shaping and planing, they are different in many aspects, as discussed below.

Similarities between shaping and planing

- Both shaping and planing are conventional machining operations that follow subtractive manufacturing approach (layer-by-layer removal of material from a solid blank).

- Both utilizes general purpose machine tools (shaping machining and planing machine).

- None of them utilize any rotational motion (as in case of turning, milling or drilling). Only reciprocating motion is used to impart required cutting velocity, feed and depth of cut.

- Areas of application of both the processes are also similar. This includes making straight slots, grooves, pockets, T-slots, V-blocks, etc.

- None of them can produce any curved slots (like circular or parabolic slot).

- In both the cases, excess material is removed from the workpiece in the form of chips (this is unlike non-traditional machining processes where material can be removed in various forms including ions, atoms, vapor, solid debris, etc.).

- Both utilize single point cutting tool (shaping tool and planing tool have only one active cutting edge that participates in material removal action at a time).

- Quick return mechanism is employed in both the machine tools; however, their point of application are different.

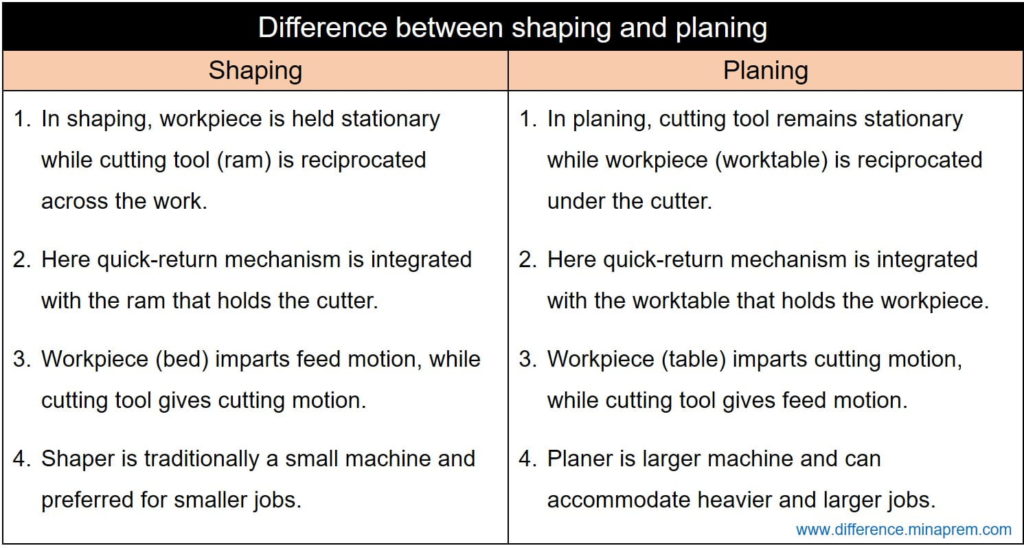

Differences between shaping and planing

| Shaping | Planing |

|---|---|

| Shaping is one machining operation where workpiece is held stationary while cutting tool (ram) is reciprocated across the work. | Planing is similar machining operation but here the cutting tool remains stationary while workpiece (worktable) is reciprocated under the cutter. |

| Workpiece (bed) imparts feed motion, while cutting tool gives cutting motion. | Workpiece (table) imparts cutting motion, while cutting tool gives feed motion. |

| Shaping operation is performed in a machine tool called Shaper (also called shaping machine). | Planing operation is performed in a machine tool called Planer (also called planing machine). |

| Here quick-return mechanism is integrated with the ram that holds the cutter. So shaping machine uses quick return mechanism for tool movement. | Here quick-return mechanism is integrated with the worktable that holds the workpiece. SO planing machine uses quick return mechanism for worktable movement. |

| Shaper is traditionally a small machine and preferred for smaller jobs. | Planer is larger machine and can accommodate heavier and larger jobs. |

| It provides low MRR, thus shaping is less productive. | Planer has longer stroke length and can take heavy cuts, so MRR is high and the operation is productive. |

| Only one cutting tool can be used at a time. | Facility to accommodate multiple tools and simultaneously using all of them is also available in some planing machines. |

References

- Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- DeGarmo’s Materials and Processes in Manufacturing by J. T. Black and R. A. Kohser (Wiley).