In the field of mechanical engineering, “Machine” is defined as an assembly of mechanisms that are clustered together in such a way that it can perform certain operations by utilizing electrical, mechanical, hydraulic and/or pneumatic power, and thereby reduces the requirement of human effort and intervention in doing the task. However, “Machine Tool” is not exactly same with the machine. The term Machine includes wide variety of machinery, whereas Machine Tools are all such machines that possess the following characteristics.

- Machine Tools must be power driven (human operated machines are not machine tools).

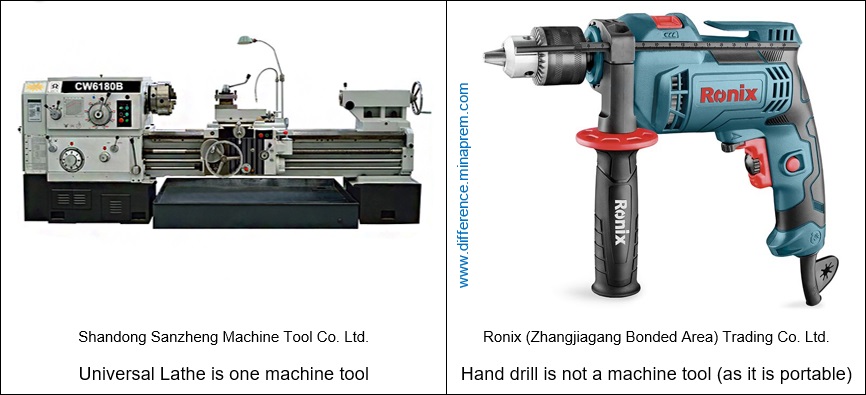

- Machine Tools must be non-portable (portability is irrespective of size). So machine tools are always firmly installed with the ground.

- Machine Tools must have sufficient value (value in terms of capability and performance, not on the basis of cost).

- Machine Tools should be able to perform more than one type of machining or metal cutting operations. (Examples of machining operation include straight turning, taper turning, internal turning, threading, facing, drilling, boring, reaming, tapping, milling, shaping, planing, slotting, broaching, hobbing, grinding, etc.).

- Machine Tools should utilize a cutting tool to shear off excess materials from workpiece in the form of chips.

If and only if all of the above five conditions are satisfied by a particular machine then it can be called a Machine Tool. Hence, all machine tools are basically machines, but not vice versa. Examples for machine tool include lathe, milling, shaping, etc. It is worth mentioning that usage of the phrase Machine Tool is confined to the metal cutting field only.

Functions of a machine tool

- It transmits power from the prime mover (such as electric motor) to the required location as and when necessary for cutting or machining action.

- It provides necessary motions to accomplish cutting action. Such motions include, but not limited to, cutting velocity, feed motion, depth of cut, etc.

- It also manipulates power and motion, including transformation of one type of motion to another type (such as rotation to translation or oscillation), reduction or increase of speed, changing the direction of rotation, etc.

- It supports and holds workpiece and other necessary devices, such as cutting tool, coolant pipeline, etc.

- It also transmits cutting force and vibration to the ground.

- Usually, it provides a better cutting fluid discharge facility.

- Finally, it provides an ergonomic platform for human workers to carry out machining.

Why lathe is not a machine?

By the definition of machine, any kind of lathe can be called a Machine! However, in the metal-working or machining field, it is commonly (sometimes mandatorily) termed as a machine tool. Since lathe qualifies all five conditions as mentioned above, so it is one machine tool. The term ‘Machine Tool’ has special significance in metal-working field as it indicates the worth of a particular machine. Traditionally it is also believed that operation on lathe is mandatory for making any mechanical product even for making another machine tool. Due to its extreme capability, people associated with metal-working field love to designate lathe as a machine tool. Therefore, lathe is not a machine; it is a machine tool.