Machining is one type of manufacturing process where excess material is removed from the workpiece to impart intended shape, size and finish. It follows the principle of subtractive manufacturing approach to build 3-D components. Conventional machining processes employ a cutting tool that contain one or more shape edges, and layer by layer material is removed from the workpiece in the form of solid chips. In order to process a wide variety of materials in different ways, there exist several conventional machining processes, namely straight turning, taper turning, internal turning, facing, threading, grooving, knurling, chamfering, face milling, peripheral milling, end milling, shaping, drilling, boring, reaming, broaching, etc. Each of these processes employs a specific cutting tool and can produce specific type of feature. Drilling is performed to originate a hole on solid surface using a cutting tool called drill. End milling is performed to cut features like slot, walls, fins, columns, webs, etc. The cutting tool employed in end milling operation is called end-mill. A drill is somewhat similar (apparently) to an end-mill. However, there exist several differences between a drill and an end mill.

Metal cutting drills (twist drills) typically have two cutting edges that are located only at the bottom cone of the drill body. There exists no cutting edge at the periphery of the drill. So entire cutting operation is performed by the bottom face, and thus feed is always given in axial direction to make a hole. It is not possible to give feed in any direction other than drill axis. Thus drills are suitable for vertical plunging only. On the contrary, end mills have main cutting edges located on the periphery of the tool body and auxiliary cutting edges located at the bottom of the tool. An end milling can contain up to 16 cutting edges. For flat end mills, ideally the feed can be given in a direction perpendicular to the tool axis. However, for rounded-corner end mills or ball end mills, small feed can also be given in axial direction. Thus, end mills are not suitable for only plunging, rather they are suitable for peripheral cutting with a small amount of plunging. Furthermore, all cutting edges present on the drill body remain in continuous contact with the workpiece during entire operation. End milling is one intermittent cutting process where each cutting edge simultaneously engages and disengages with workpiece in every rotation of the tool. The engagement angle, however, depends on radial immersion. Several similarities and differences between drill and end mill are provided below in table format.

Similarities between drill and end mill

- Both are multi-point cutters as more than one active cutting edges participate in material removal action. It is worth noting that micro-end mills (tool diameter is about 10-50 μm) may also have only one cutting edge; however, such tools are not commonly used.

- In both the cases, material removal takes place in the form of solid chips.

- In both the cases, the cutting velocity is provided through the rotation motion of the cutting tool (drill or end mill). Such velocity is also proportional to the tool diameter and rotation speed.

- Due to physical contact between tool and workpiece, several problems such as tool wear, residual stress, heat generation, etc. are encountered in both the operations.

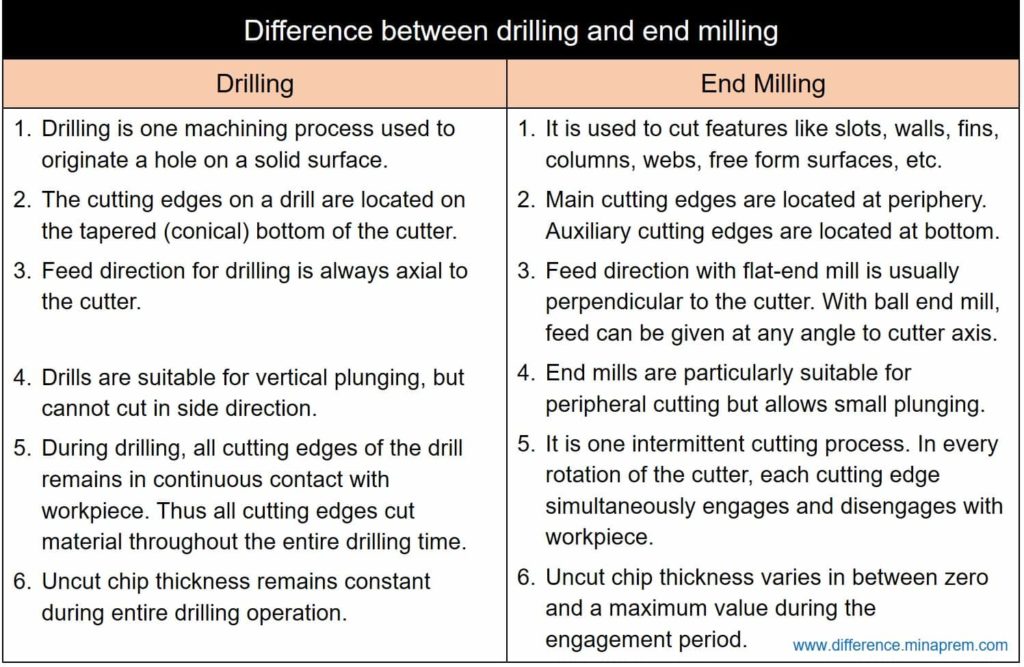

Differences between drill and end mill

| Drill (Drilling) | End Mill (End Milling) |

|---|---|

| Drill is the cutting tool used for drilling operation. Drilling is one machining process used to originate a hole on a solid surface. | End mill is the cutting tool used for end milling operation. End milling is a machining process used to cut features like slots, channels, walls, fins, columns, webs, free form surfaces, etc. |

| The cutting edges on a drill are located on the tapered (conical) bottom of the cutter. | Main cutting edges on an end mill are located at the periphery of the cutter. Auxiliary cutting edges are present at the bottom. |

| Metal cutting drills (twist drills) typically have two cutting edges. However, wood cutting drills can have 3 or 4 cutting edges. | End mills can have a wide variety of cutting edges (or flutes), ranging from just 1 (in micro end mills) to as high as 16. |

| Feed direction for drilling is always axial to the cutter. | Feed direction in end milling with flat-end mill is usually perpendicular to the cutter. With ball end mill, feed can be given at any angle to the cutter axis. |

| Drills are suitable for vertical plunging, but cannot cut in side direction. | End mills are particularly suitable for peripheral cutting. However, small plunging is permitted in ball end milling. |

| Drill cannot generate plain surface. It generates one cylindrical surface at periphery and one conical surface at bottom (in blind hole drilling only). | End milling can generate plain surfaces. With flat end mills, one flat surface is generated at bottom and two vertical flat surfaces are generated at two sides. |

| Conventional drill cutters are mostly made of HSS (High Speed Steel). | End mills are commonly made of WC (Tungsten Carbide), coated or uncoated, insert type or plain. |

| Drills can produce features (holes) of high aspect ratio (hole axial length to hole diameter), even up to 10:1. | End milling is commonly not used when aspect ratio exceeds 2:1. |

| Usually low rotational speed is used in drilling as high rpm of the drill can create problem in chip evacuation and can lead to breakage of the drill. | End milling can be carried out at high rotational speed of the cutter. |

| During drilling, all cutting edges of the drill remains in continuous contact with workpiece. Thus all cutting edges cut material throughout the entire drilling time. | End milling is one intermittent cutting process. In every rotation of the cutter, each cutting edge simultaneously engages and disengages with workpiece. So each cutting edge cuts material from workpiece only for a portion of time for every rotation of the tool. |

| Uncut chip thickness for each cutting edge remains constant during entire drilling operation. | In end milling, the uncut chip thickness does not remain constant, rather varies in between zero and a maximum value during the engagement period in every rotation for each cutting edge. |

| In drilling, feed motion can be imparted either by moving the tool or by moving the workpiece. | In end milling, feed motion is usually imparted by moving the workpiece. |

| Drilling can generate long continuous chip as cutting edges remain in continuous contact with workpiece. | End milling inherently generates discontinuous chips owing to repeated engagement and disengagement of cutting edges with workpiece. |

References

- Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Saha et al. (2020); An analytical approach to assess the variation of lubricant supply to the cutting tool during MQL assisted high speed micromilling; Journal of Materials Processing Technology. https://doi.org/10.1016/j.jmatprotec.2020.116783

- Saha et al. (2020); An investigation on the top burr formation during Minimum Quantity Lubrication (MQL) assisted micromilling of copper; Materials Today: Proceedings; https://doi.org/10.1016/j.matpr.2020.02.379