Conventional machining operation utilizes a wedge shaped cutting tool having one or more sharp cutting edges to facilitate shearing. To achieve material removal, three relative motions between workpiece and cutting tool are indispensably necessary. These are also called process parameters. One of such three relative motions is cutting velocity, other two being feed motion and depth of cut. In few machining processes, the cutting velocity is imparted either by rotating the workpiece or by rotating the cutter. For example, in lathe operations like turning, threading, face turning, parting, grooving, drilling, etc. the workpiece is rotated, while the cutting tool is rotated in milling processes. Such rotation (workpiece or cutter) can be expressed in two different ways, namely cutting speed and cutting velocity.

Cutting speed is basically the rotational speed of either workpiece or cutting tool (whichever is rotating, based on the machining operation). It is measured by the unit revolution per minute (rpm) and usually designated by N. On the other hand, cutting velocity is the tangential velocity of either rotating workpiece or rotating cutting tool. It is usually measured by the unit meters per minute (m/min) and designated by Vc. However, there exist few machining operations where neither workpiece nor cutting tool rotates; instead, they undergo linear reciprocating motions, for example, shaping or planing operation. For such cases, this linear velocity of workpiece or cutting tool (whichever is reciprocating) is termed as cutting velocity. Cutting speed becomes invalid in such scenario, as there is no rotational object. Various similarities and differences between cutting speed and cutting velocity are explained in the following passages.

Similarities between cutting speed and cutting velocity

- Both cutting speed and cutting velocity are interrelated and one is proportional to another.

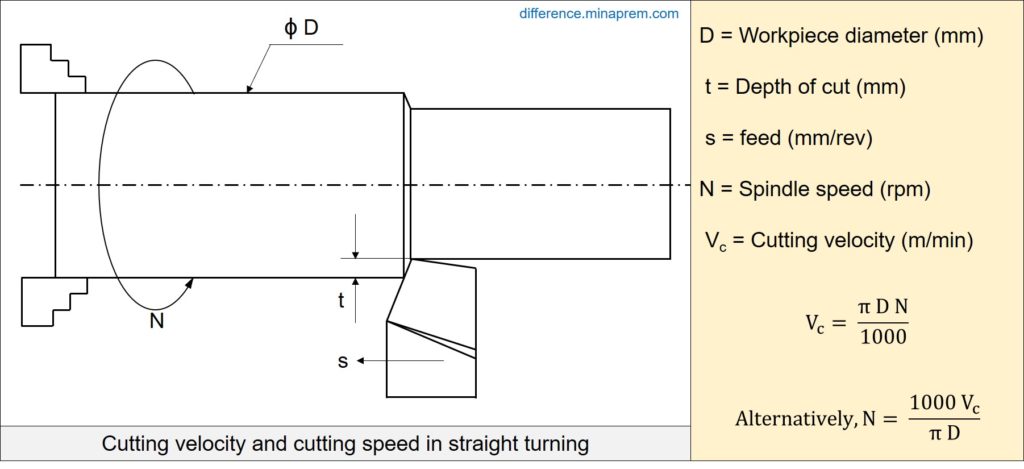

- One can easily be converted to another, provided that the diameter of either cutter or workpiece (the rotating one) is known. The following formula can be employed to convert cutting speed into cutting velocity or vice versa.

Differences between cutting speed and cutting velocity

| Cutting Speed | Cutting Velocity |

|---|---|

| Cutting speed indicates the rotational speed of either workpiece or cutting tool. | Cutting velocity indicates the tangential velocity of either rotating workpiece or rotating cutting tool. |

| It is commonly expressed in revolution per minute (rpm). | It is commonly expressed in meters per minute (m/min). |

| Cutting speed is a scalar quantity. | Cutting velocity is one vector quantity. |

| It is usually not considered as a machining process parameter. | It is considered as one crucial machining process parameter. |

| Cutting speed is only associated with those machining operations where either workpiece or cutting tool rotates. | Cutting velocity is associated with all conventional machining operations irrespective of presence or absence of rotation of workpiece or cutting tool. |

| Cutting speed is mainly useful during operating the machines (including conventional one and CNC based machine tools). | Cutting velocity is useful in various analysis, such as assessment of cutting force, temperature, vibration, machinability, economy of machining, etc. |