In every arc welding process, an electric arc is constituted between the electrode and the conductive base metals. This arc supplies necessary heat to fuse the faying surfaces of the base plates. There are several arc welding processes, namely, manual metal arc welding, gas metal arc welding, gas tungsten arc welding, flux core arc welding, submerged arc welding, etc. Each process has unique characteristics and offers several benefits compared to others. The gas metal arc welding (GMAW) process employs a consumable wire electrode to supply filler metal into the welding zone. This wire electrode is wrapped in a wire-pool and is continuously fed to the welding zone with the help of an automatic arrangement. To protect the hot weld bead from undesired oxidation and contamination, shielding gas is also supplied in the welding zone from a separate gas cylinder. Based on the constituent of shielding gas, the GMAW process can be classified into two groups – Metal Inert Gas (MIG) welding and Metal Active Gas (MAG) welding. As the name suggests, inert gas like argon, helium, nitrogen, or a mixture of such gases is used as shielding gas in MIG welding. On the other hand, a mixture of active gases (oxygen or carbon dioxide) and inert gases is used as shielding gas in MAG welding. Thus, MIG welding is basically a GMAW process where only inert shielding gas is supplied.

Tungsten Inert Gas (TIG) welding, also called Gas Tungsten Arc Welding (GTAW) is another fusion welding process where the electric arc is established between a non-consumable tungsten electrode and the conductive bade plates. Since the electrode is non-consumable, so filler metal can also be supplied additionally by feeding a filer rod beneath the arc. However, TIG welding is preferred for autogenous welding where no filler metal is added to join the components. Unlike MIG welding where the electrode material is selected based on the composition of base metal, TIG welding utilizes a tungsten electrode irrespective of the chemical composition of the base metals. TIG welding also employed inert shielding gas to protect the hot weld bead from oxidation and contamination. If carried out properly, TIG welding can produce a defect-free sound joint with very good appearance. Moreover, it does not produce any spatter. Various similarities and differences between MIG welding and TIG welding are given below in table format.

Similarities between MIG and TIG welding

- Both the TIG and MIG welding are basically arc welding processes as electric arc is constituted between the electrode and the base plates to melt down the faying surfaces and to form the coalescence. They also come under fusion welding processes as base metals are fused during joining.

- Both the processes utilize bare electrode. Although the electrode material is different in these two processes, but no flux-coated electrode is employed in any of these two processes.

- In both the cases, shielding gas is required to supply from additional sources. This is unlike MMAW or FCAW process where shielding gas is inherently obtained during the process due to the disintegration of the flux available with the electrode.

- Inert shielding gas is used in both the cases to protect hot weld bead from oxidation and contamination. Only inert gases like argon, helium, nitrogen, or a mixture of such gases are employed for shielding purpose.

- Only conductive metals can be joined by these two processes. In fact, all arc welding processes are applicable to conductive metals only. Solid state welding can be applied for joining non-conductive metals.

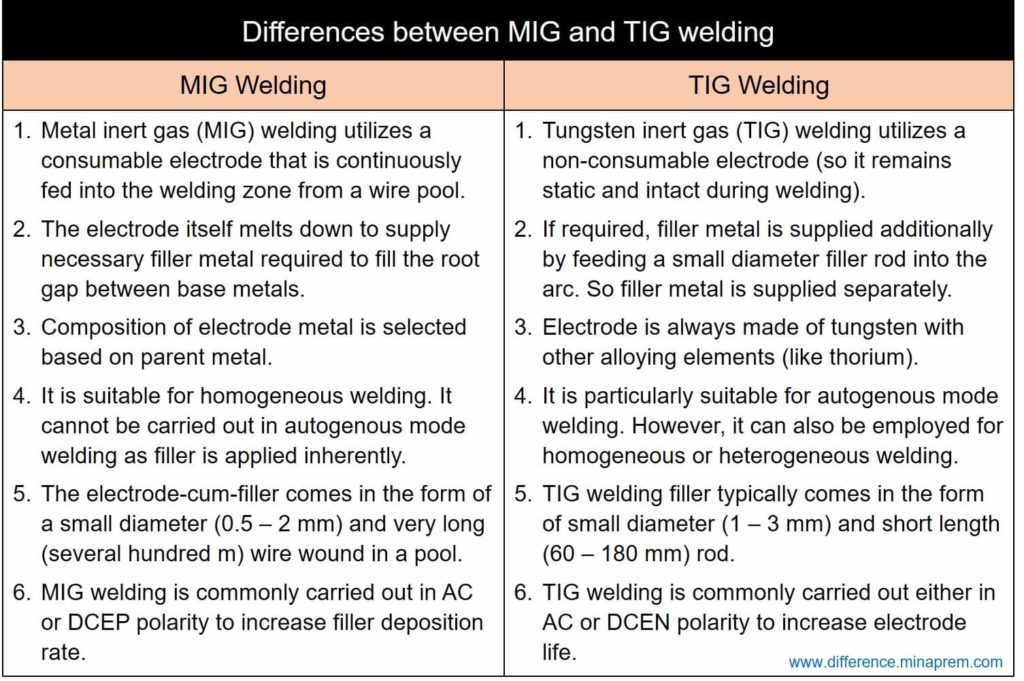

Differences between MIG and TIG welding

| MIG Welding | TIG Welding |

|---|---|

| Metal inert gas (MIG) welding utilizes a consumable electrode that is continuously fed into the welding zone from a wire pool. | Tungsten inert gas (TIG) welding utilizes a non-consumable electrode (so it remains static and intact during welding). |

| The electrode itself melts down to supply necessary filler metal required to fill the root gap between base metals. So electrode acts as filler metal (no additional filler is required). | If required, filler metal is supplied additionally by feeding a small diameter filler rod into the arc. So filler metal is supplied separately. |

| Composition of electrode metal is selected based on parent metal. Usually, metallurgical composition of electrode metal is similar to that of base metal. | Electrode is always made of tungsten with small proportion of other alloying elements (like thorium). |

| It is suitable for homogeneous welding. It cannot be carried out in autogenous mode welding as filler is applied inherently. | It is particularly suitable for autogenous mode welding. However, it can also be employed for homogeneous or heterogeneous mode by supplying additional filler. |

| The electrode-cum-filler for MIG welding comes in the form of a small diameter (0.5 – 2 mm) and very long (several hundred meters) wire that is wound in a wire-pool. | TIG welding filler typically comes in the form of small diameter (1 – 3 mm) and short length (60 – 180 mm) rod. |

| Due to very large length, the filler electrode can be fed for a longer duration without replacement. | Due to short length, frequent replacement of filler is required. This interrupts the welding process unintentionally. |

| MIG welding is commonly carried out either in AC or in DCEP polarity so that electrode can be melted and deposited at a faster rate. | TIG welding is commonly carried out either in AC or DCEN polarity to increase electrode life. |

| Filler deposition rate is very high, so the process is highly productive. | Filler deposition rate is low. In this sense, it is not very productive. |

| MIG welding usually produce spatter. This causes loss of costly filler metal. | TIG welding is mostly free from spatter. |

| Quality and appearance of weld bead are not very good. | It can easily produce defect-free reliable joint with good appearance. |

| It does not lead to tungsten inclusion defect. | TIG welding sometimes leads to tungsten inclusion defect (occurred when a melted/broken part of the tungsten electrode gets embedded into weld bead). |

Reference

- Comprehensive Workshop Technology (Manufacturing Processes) by S. K. Garg (Laxmi Publications Private Limited).

- Manufacturing Technology: Foundry, Forming and Welding by P. N. Rao (Tata McGraw Hill Education Private Limited).

- A Text-Book of Welding Technology by O. P. Khanna (Dhanpat Rai Publications).