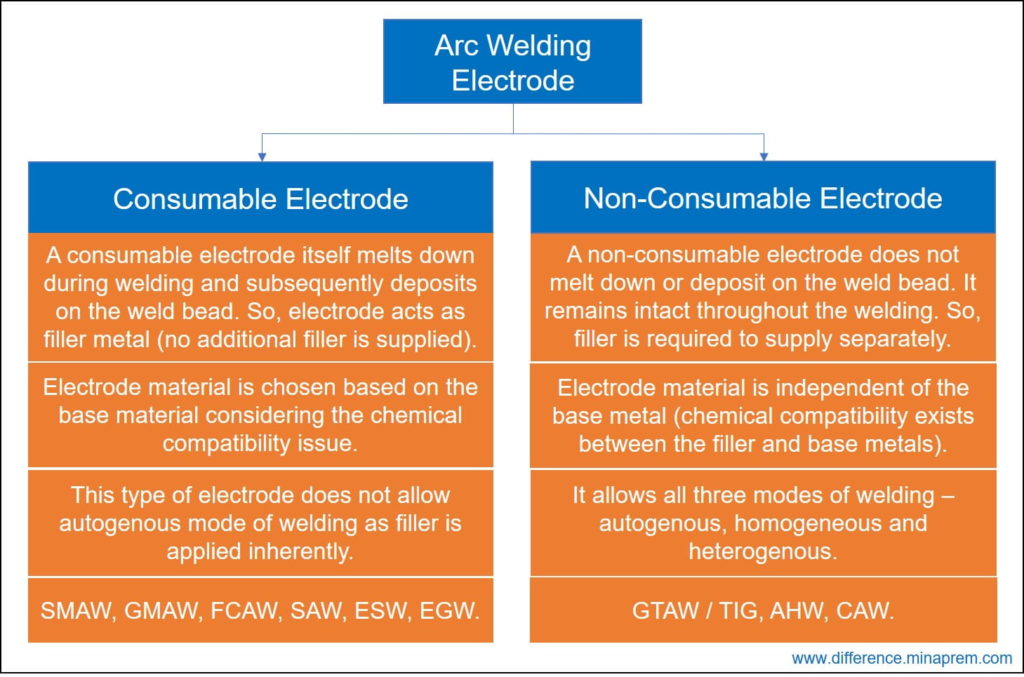

Arc welding is one type of fusion welding process where an electric arc is used to supply heat for melting the faying surfaces of the parent metal and also the filler metal. There are several arc welding processes namely Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), Flux Cored Arc Welding (FCAW), Submerged Arc Welding (SAW), Electroslag Welding (ESW), Carbon Arc Welding (CAW), Electro-Gas Welding (EGW), etc. Irrespective of the welding process, the arc is always constituted between an electrode and the conductive base metals. In some arc welding processes, the electrode is consumed during welding to supply necessary filler; while in other processes, the electrode remains unaffected. Based on the consumption of electrode material during welding, welding electrodes can be classified as consumable electrode and non-consumable electrode. Each type of electrode has unique benefits and limitations.

During arc welding, a consumable electrode melts down due to arc heating and subsequently deposits on the weld bead. Since electrode itself supplies necessary filler to fill the root gap between parent components, so additional filler is not required to supply. Obviously, the melted portion of the electrode finally becomes an integrated part of the weld bead. Due to continuous consumption of electrode, its life is short. Material of a consumable electrode should be selected based on the workpiece material as chemical compatibility is highly desired for coalescence formation. Arc welding processes like SMAW, GMAW, SAW, FCAW, ESW, etc. employed a consumable electrode. On the other hand, a non-consumable electrode does not fuses or deposits on the weld bead in any stage of the welding. Here the electrode is used only to establish and maintain the electric arc. Filler material, if required, is required to supply separately. Thus the electrode exhibits a longer life. Here the compatibility issue exists in between the filler metal and base metals, and hence electrode material is independent of the base metals to be joined. TIG welding is a common example that employs a non-consumable tungsten electrode. Various similarities and differences between consumable electrode and non-consumable electrode are given below in table format.

Similarities between consumable and non-consumable electrode

- The role of electron emission and arc formation is same for both the consumable and non-consumable electrodes.

- With consumable as well as non-consumable electrodes, the faying surface of the base metals and also the filler metal are melted during arc welding for coalescence formation.

- Shielding gas is required with both the electrodes to protect the hot weld bead from undesired oxidation and contamination. However, source of shielding gas can vary from one welding process to another.

Differences between consumable and non-consumable electrode

| Consumable Electrode | Non-Consumable Electrode |

|---|---|

| A consumable electrode itself melts down during welding and subsequently deposits on the weld bead. | A non-consumable electrode does not melt down or deposit on the weld bead. It remains intact throughout the welding. |

| A consumable electrode acts as filler and thus it supplies necessary filler material intended to fill the root gap. | Non-consumable electrode does not supply filler. Thus filler material is required to supply separately. |

| After welding, a significant portion of the electrode becomes an integrated part of the weld bead. | After welding, the electrode remains unaffected (except a small erosion). |

| This type of electrode does not allow autogenous mode of welding as filler is applied inherently. It can be used for either homogeneous or heterogeneous mode of welding. | It allows all three modes of welding – autogenous, homogeneous and heterogeneous. |

| Electrode material must be chosen based on the parent materials in order to maintain chemical compatibility between them. | Since non-consumable electrode does not act as filler, so electrode material is independent of the parent materials to be welded. |

| Since electrode material is consumed during welding, so frequent replacement of the electrode is usually desired. However, the replacement frequency depends on electrode size and filler deposition rate. | A non-consumable electrode offers extended life as it is not consumed during welding. Frequent replacement is also not desired (it helps improving productivity). |

Arc welding processes that employ a consumable electrode:

|

Arc welding processes that employ a non-consumable electrode:

|

Reference

- Manufacturing Technology: Foundry, Forming and Welding by P. N. Rao (Tata McGraw Hill Education Private Limited).

- A Text-Book of Welding Technology by O. P. Khanna (Dhanpat Rai Publications).