Arc welding is one type of fusion welding process where an electric arc is used to supply necessary heat for fusing the faying surfaces of the base metals and also the filler metal. In every arc welding process, the conductive base plates are connected with one terminal of the power source, while the electrode is connected with other terminal. A small gap (1 – 3mm) is always maintained between the electrode and the base metals. When sufficient potential difference is applied across these two, electrons flow from the negative terminal to the positive terminal in the external circuit. Flow of avalanche of electrons ultimately constitutes the electric arc, which is prime source of heat. Polarity in arc welding process decides the direction of electron flow between base plates and electrodes. Electrons always flow from the negative electrode to the positive electrode in an external circuit. In arc welding, if the welding electrode is connected with the negative terminal then electrons will flow from the electrode to the base metals, or vice versa. Arc welding power sources provide either AC or DC power; however, depending on the connection made, DC power can provide two polarities – straight polarity and reverse polarity, as described below.

Direct Current Straight Polarity (DCSP) or Direct Current Electrode Negative (DCEN): It occurs when electrode is connected with the negative terminal of the power source and base metals are connected with the positive terminal. So with DCSP polarity, avalanche of electrons are liberated from the electrode and flow towards the base plates. Due to presence of sufficient potential difference, electrons are accelerated between the electrode and base metals, and finally strike the base metal surface at very high velocity. Upon striking, the kinetic energy of the electrons are converted into thermal energy and thus immense heat is generated at the vicinity of the base plate surface. As a thumb rule, it is considered that about 66% of the total arc heat is generated on the base metal surface, while rest of the heat is generated at the electrode surface. This helps in quick melting of the base plates and thus deeper penetration can be achieved easily. However, filler metal deposition rate reduces due to less heat near electrode, especially in consumable electrode based welding.

Direct Current Reverse Polarity (DCRP) or Direct Current Electrode Positive (DCEP): Here the base metals are connected with the negative terminal of the power source, while the electrode is connected with the positive terminal. Thus electrons are emitted from the base plates and flow towards the electrode. Accordingly, majority of the arc heat is generated at the electrode surface, while less heat is generated on base metals surface. This leads to the higher filler deposition rate (with consumable electrode). Insufficient fusion of the base metal may be noticed due to lack of heat. However, when the avalanche of electrons liberate from the base plate, the dirt and oxide layers on the base metals get ruptured. This phenomenon is also termed as arc cleaning action. This is beneficial as it inherently removes contaminated particles from the faying surfaces and thus helps in achieving defect-free weld bead.

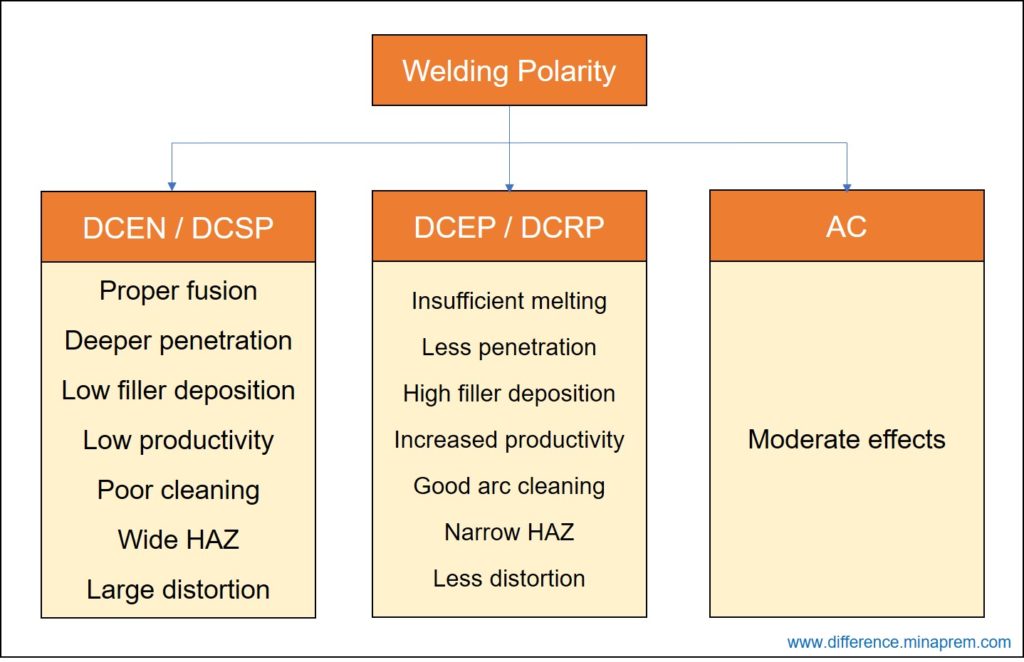

Both DC Straight Polarity and DC Reverse Polarity have respective pros and cons. In AC power supply, the polarity reverses repeatedly for certain number of times in every second (based on frequency of the supply). Thus AC polarity provides a moderate effects. Various similarities and differences between Direct Current Straight Polarity (DCSP) and Direct Current Reverse Polarity (DCRP) are tabulated below.

Similarities between DCEN and DCEP polarities in arc welding

- Both DCSP and DCRP can be applied for joining of two or more components together; however, the result may be substantially different.

- Both the polarities constitute electric arc (prime source of heat in arc welding).

- Both occur repeatedly one after another in every cycle in case of AC supply.

Differences between DCEN and DCEP polarities in arc welding

| DCSP / DCEN | DCRP / DCEP |

|---|---|

| In Direct Current Straight Polarity, electrode is connected with the negative terminal of the power source and base metals are connected with the positive terminal. | In Direct Current Reverse Polarity, base metals are connected with the negative terminal of the power source and electrode is connected with the positive terminal. |

| Under sufficient potential difference, electrons liberate from the tip of the electrode and strike the base metal surface. | Here electrons liberate from the base metal surface and strike the electrode tip. |

| Almost 2/3rd of the total arc heat is generated near base plate and rest is generated at electrode tip. | Here, 2/3rd of the total arc heat is generated at electrode tip and rest is generated near base plate. |

| Proper fusion of the base metal can be achieved easily with straight polarity as more heat is generated at the vicinity of base metals. So it eliminates lack of fusion and lack of penetration defects. | Due to less heat generation near base metal, incomplete fusion of the base metal may be encountered. This may lead to lack of fusion and lack of penetration defects. |

| In case of consumable electrodes, filler metal deposition rate is quite low. | Filler metal deposition rate with consumable electrodes is high as greater portion of arc heat is generated at electrode tip. |

| Oxide cleaning action by the arc is poor. | Oxide cleaning action by the arc is good as electrons are liberated from the base metal surface. |

| Inclusion defects may arise if base plate surfaces are not cleaned properly prior to welding. | Due to good arc cleaning action, tendency of inclusion defects reduces. |

| DCSP may result in high distortion and broader HAZ in the welded component. | Distortion is less with DCRP and also HAZ is quite thin. |

| DCSP is not suitable for welding thin plates as it may lead to cutting instead of welding. | DCRP is suitable for welding thin plates. |

| Metals with high melting temperature (such as stainless steel, titanium) can be advantageously joined by DCSP. | Metals with low melting temperature (such as copper, aluminum) can be suitably joined by DCSP. |

References

- Manufacturing Technology: Foundry, Forming and Welding by P. N. Rao (Tata McGraw Hill Education Private Limited).

- A Text-Book of Welding Technology by O. P. Khanna (Dhanpat Rai Publications).

- Welding Metallurgy by S. Kou (Wiley India).

- Welding Processing and Technology by R. S. Parmar (Khanna Publishers).