Like welding, riveting is also one permanent joining process used for mechanical assembly of two or more solid components. In riveting, arrays of through holes are first drilled on the components in pre-defined locations. Additional strap plates, if used, are also drilled in the corresponding locations. Rivets of specific dimension are then inserted via these holes. The diameter of the drilled hole on the components is larger than the shank diameter of the rivets but smaller than the diameter of the rivet head. Length of the rivet shank must be substantially larger than the cumulative width (or thickness) of the components and additional straps. the protruding portion of the rivet shank is upset by hammering to produce a closing head in opposite side of the rivet heat. Stress (tensile or compressive, based on riveting method) developed within the rivets helps tightly mounting the components. The magnitude of compressive force required for upsetting the protruding end of the rivet mainly depends on the rivet size and rivet material. Such force or pressure requirement can be substantially reduced by heating the protruding end of the rivet prior to upsetting. Accordingly, two different riveting methods have evolved – hot riveting and cold riveting.

When the protruding end of the rivet shank is heated to an elevated temperature before upsetting, then it is termed as hot riveting. The temperature usually lies in between 50% – 70% of the melting point of the rivet material. The biggest advantage that can be achieved due to heating is the substantial reduction of hammering force or pressure requirement for the same rivet size and material. Additionally, it offers a tight clamping and better leak-proof joints. However, it requires external heat source and thus additional accessories and corresponding cost. Moreover, it is not suitable for heat sensitive materials. In cold riveting, the protruding end of the rivet shank can be directly hammered without heating (i.e. upsetting is carried out at room temperature). Although it does not require heat source, it is not efficient for large diameter rivets as very high compressive force is desired for upsetting. Various similarities and differences between hot riveting and cold riveting are given below in table format.

Similarities between hot riveting and cold riveting

- Both hot riveting and cold riveting are permanent joining techniques. They also fall under mechanical joining techniques (contrary to chemical joining techniques like adhesives).

- Both the riveting techniques require pre-drilled holes on the components for the passage of rivets. Such holes lead to stress concentration and considerably reduce load carrying capacity of the assembled structure due to reduction of cross-sectional area.

- Both require hammering or upsetting for making a closing head at the protruding end of rivet shank; however, intensity of hammering force differs.

- Strap plates can be used in both the cases if required.

- Both offer an intermittent joints (rather than a continuous joint as in case of adhesive joint or welded joint).

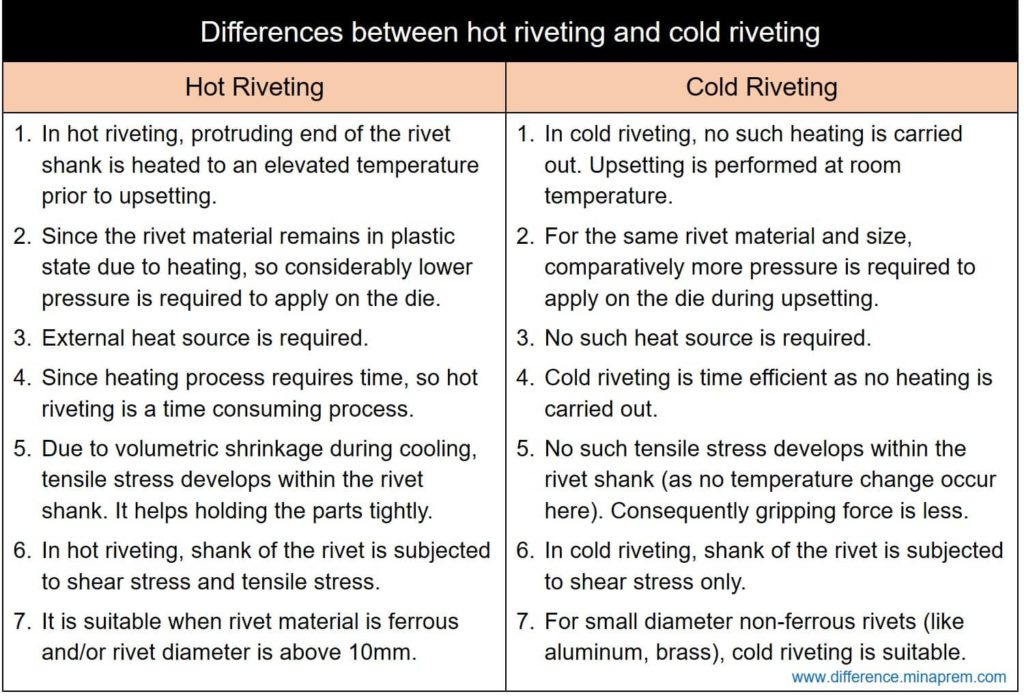

Differences between hot riveting and cold riveting

| Hot Riveting | Cold Riveting |

|---|---|

| In hot riveting, protruding end of the rivet shank (opposite to head) is heated to an elevated temperature (about 2/3rd of the melting temperature of the rivet material). So upsetting is carried out at elevated temperature. | In cold riveting, no such heating is made. Upsetting is carried out at room temperature. |

| For hot riveting, the rivet material remains in plastic state due to heating, and thus considerably lower pressure is required to apply on the die. | In cold riveting, comparatively more pressure is required to apply on the die for the same rivet material and size. |

| External heat source is required to elevate the rivet temperature. | No such heat source is required. |

| Since heating process requires time, so hot riveting is a time consuming process. | Cold riveting is time efficient as no heating is carried out. |

| Due to automatic volumetric shrinkage during cooling (after the upsetting), tensile stress develops within the rivet shank. It helps holding the assembled parts tightly. | In cold riveting, no such tensile stress develops within the rivet shank (because temperature change does not occur here). Consequently gripping force is less. |

| Due to strong gripping force, joints are usually leak-proof. | Cold riveting is not recommended for fluid-tight joining purposes. |

| In hot riveting, shank of the rivet is subjected to shear stress and tensile stress. | In cold riveting, shank of the rivet is subjected to shear stress only. |

| It is suitable when rivet material is ferrous and/or rivet diameter is above 10mm. | For non-ferrous rivets (such as aluminum, brass, etc.) of small diameter, cold riveting can be conducted. |

References

- Introduction to Machine Design by V. B. Bhandari (McGraw Hill Education India Private Limited).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand).

- Theory of Machines by R. S. Khurmi and J. K. Gupta (S. Chand).