Macro-scale hole fabrication on a solid surface requires several different metal cutting operations based on the size and accuracy requirement. One typical series for hole making can be— (i) Centering, (ii) Drilling, (iii) Boring, (iv) Reaming and (v) Honing. Centering is carried out to locate the hole for easy and accurate alignment of a drill. Although it is optional, but centering can improve precision. Drilling is a process of originating a hole, while boring enlarges the diameter of an existing hole. Reaming and honing are used to improve the surface finish and tolerance of the existing hole. Various similarities and differences between drilling, boring and reaming processes are discussed in following sections.

Similarities between drilling, boring and reaming

- Drilling, boring and reaming — all three processes are associated with hole fabrication.

- All three processes follow subtractive manufacturing approach (top-down approach). So excess material is gradually removed from the workpiece in the form of chips.

- Cutting tool is inherent in all three processes; however, their shape and feature are different for different processes.

- Chips are also inherently produced in all the processes.

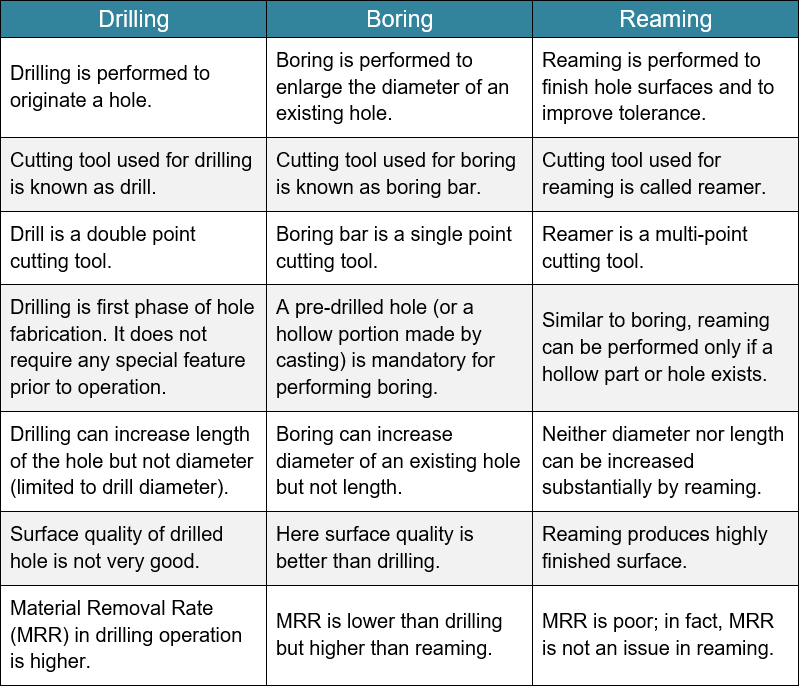

Differences between drilling, boring and reaming

Purpose of operation

- Drilling is carried out to originate a cylindrical hole. So it can create a hole on a solid surface.

- Boring is performed to enlarge an existing hole or to convert a cylindrical hole into a taper hole.

- Reaming is carried out to highly finish the surfaces of a hole. Its purpose is to improve dimensional accuracy and tolerance.

Initial requirement

- Drilling does not require any special feature for it. However, centering can be done prior to drilling to improve accuracy. Centering is one optional step.

- Boring requires an existing hole for its operation. Such holes can be made either by drilling or by casting.

- Reaming also requires a cylindrical hole for its operation. Here the hole diameter should match with reamer diameter.

Cutting tool used

- Drilling utilizes a double point cutting tool called drill. So metal cutting drills have only two cutting edges that simultaneously participate in cutting action.

- Boring utilizes a single point cutting tool called boring bar. The tool is similar to single point turning tool (SPTT) and the operation is also similar to internal turning.

- Reaming utilizes a multi-point cutting tool called reamer. It consists of at least four cutting edges.

Capability to alter diameter and length of hole

- In drilling, diameter of the hole depends on selected drill diameter. Hole diameter is always same with drill diameter. However, length of hole can be increased during operation (by plunging the drill against the work surface).

- Boring is performed to increase diameter of an existing hole. It can also make a taper hole from a cylindrical one. However, it cannot increase length of the hole (as it does not allow plunging).

- Reaming is basically finishing process that can marginally increase hole diameter. Length of the hole cannot be increased by reaming.

Quality of surfaces of hole

- Drilling does not provide a highly finished surface. Typical surface roughness in drilling is in the order of 2 – 10μ

- Boring can provide comparatively better surface (typically 1 – 5μm).

- Reaming is performed to obtain a highly finished surface. So it provides best surface finish and accuracy among all three processes (roughness in the order of 0.2 – 1.0μm).

Possibility of making taper hole

- Taper holes cannot be fabricated by drilling alone.

- After drilling a cylindrical hole, boring can be utilized to make a taper hole.

- Reaming can be utilized for smoothening surfaces of a taper hole.

Material Removal Rate (MRR)

- Drilling undoubtedly provides high MRR. So it is suitable for stock or bulk removal.

- Boring also provides high MRR; however, lower than drilling.

- Reaming gives poor MRR; in fact, obtaining higher MRR is not the purpose of reaming. Its purpose is to obtain highly finished surface, rather than removing bulk material.