In conventional machining, the cutting tool compresses a thin layer of work material to gradually shear it off in the from of chip. Cutting tool is basically a wedge shaped device that actually shears off material from the workpiece. This cutting tool as well as the workpiece is mounted on the machine tool maintaining proper orientation. Necessary relative velocities between workpiece and cutter (in the form of cutting velocity, feed rate and depth of cut) are also provided by the machine tool. Every cutting tool should have certain pre-defined fixed features apart from basic shape and size. An appropriate cutter for a particular machining operation under given set of process parameters is selected based on these features of the cutting tool. Typical features include rake angle in different directions, clearance angle in different directions, cutting edge angles, nose radius, etc.

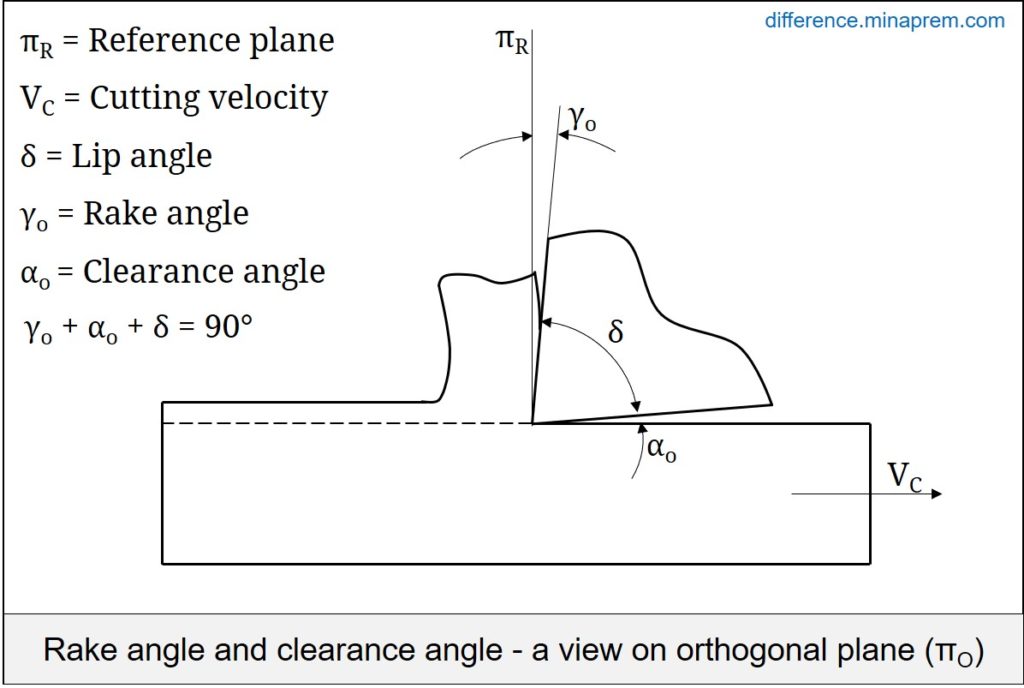

Orientation of the rake surface is denoted by rake angle. Basically rake surface is the chip flowing surface (chips initially after forming flows over the rake surface under immense contact pressure before it separates). By definition, rake angle is the angle of orientation of rake surface from the reference plane and measured on other plane. A reference plane is a standard plane normal to cutting velocity. Rake angle can be measured on different planes and the angle will be different with change in direction due to three-dimensional orientation of the rake surface (unless rake surface is parallel to reference plane). Its value determines shear deformation, chip thickness, cutting force, power, chip form, etc. On the other hand, clearance angle is the angle of inclination of flank surface from the cutting velocity vector and measured on other plane. As usual, the angle will be different based on the plane on which it is measured. This angle has no influence on shear deformation, force and power; however, it has impact on finished surface. Various similarities and differences between rake angle and clearance angle are given below.

Similarities between rake angle and clearance angle

- Rake angle and clearance angle are two important angles of every cutting tool. So their presence in every cutter is mandatory.

- These two angles are independent to each other. However, their algebraic sum with wedge angle must be equal to 90°.

- Every cutting tool should have pre-defined values for rake angle and clearance angle for efficient and uninterrupted machining with better machinability.

- Based on the direction of measurement, values of these angles will change.

- Values of both the angles in different directions or planes are absolutely necessary while fabricating or re-sharpening the cutter.

- Both the angles may change due to gradual wear of cutting tool.

Differences between rake angle and clearance angle

| Rake Angle | Clearance Angle |

|---|---|

| Rake angle is the angle between the rake surface and the reference plane as measured on another plane. | Clearance angle is the angle between the flank surface and the cutting velocity as measured on another plane. |

| Rake angle indicates orientation of rake surface of the cutting tool. | Clearance angle indicates inclination of flank surface of the cutting tool. |

| A cutter may have positive, negative or zero rake angle. Typically its value ranges from -15° to +15°. | Clearance angle is always positive (it cannot be zero or negative). Typically its value ranges from +3° to +15°. |

| Rake angle influences the extent of shear deformation of chip and also determines chip flow direction. | Clearance angle has no direct influence on shear deformation of chip and its flow direction. |

| To some extent, rake angle influences cutting force and power consumption during machining. | Clearance angle no influence on cutting force and power consumption. |

References

- Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Manufacturing Process for Engineering Materials by S. Kalpakjain and S. Schmid (Pearson Education India).