Conventional machining is one type of manufacturing process in which excess material is removed from a pre-formed blank by shearing in the form of chips using a wedge shaped cutting tool in order to get desired shape, finish and tolerance. There exist several machining processes to efficiently machine a wide variety of materials in innumerable ways. Turning and milling are just two examples of such machining processes. Others being tapering, drilling, shaping, planing, slotting, knurling, boring, reaming, sawing, chamfering, etc. Each of these processes has unique benefits and limitations, and thus is suitable for particular requirements.

Although both turning and milling follows the principles of subtractive manufacturing, their areas of application are different as they produce different geometrical surfaces. Turning is used to reduce diameter of a job, and thus provides a cylindrical surface. It is carried out in lathe with the help of a single point cutting tool (known as turning tool). Here the workpiece rotates at a fixed rpm to provide necessary cutting velocity, while the tool is moved to provide required feed. On the other hand, milling produces a flat or stepped surface. It is carried out in milling machine and it employs a multi-point cutter (milling cutter). Here the cutter rotates at fixed rpm to provide cutting velocity, while the workpiece is moved with respect to the stationary cutter to provide feed. Important similarities and differences between turning and milling are given in the following sections.

Similarities between turning and milling

- Both turning and milling are conventional machining processes. Such processes utilize a specially designed cutting tool that physically compresses a thin layer of workpiece material to gradually shear it off in the form of solid chip.

- Both turning and milling follow subtractive manufacturing approach. Here layer by layer material is removed from a solid 3-D block to obtain intended product. On the contrary, additive manufacturing approach follows the concept of addition of thin layer of material one over another to build a solid 3-D block.

- Both turning and milling processes employ a solid cutting tool to shear off material from the workpiece; however, the shape and features of the cutters for these two processes vary widely.

- Chip formation is inherent in both the cases. In fact, it is fundamental to every conventional machining process.

- Both the processes can produce reasonably good surface finish; however, it depends on several other factors including cutting velocity, feed rate, depth of cut, tool geometry, cutting environment, etc.

- Heat generation is inherent in both the processes. Consequent effects of high cutting temperature are also similar for both the operations.

- Cutting fluid can be applied in both the processes.

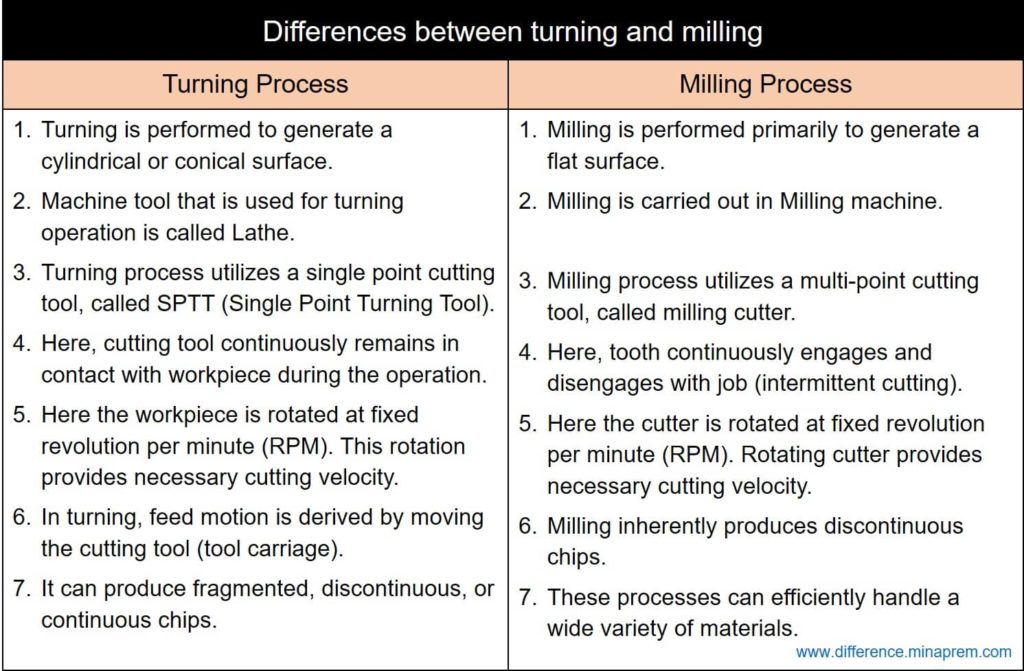

Differences between turning and milling

| Turning | Milling |

|---|---|

| Turning is performed to generate a cylindrical or conical surface. | Milling is performed primarily to generate a flat surface. |

| Machine tool that is used for turning operation is called Lathe. | Milling is carried out in Milling machine. |

| Turning process utilizes a single point cutting tool, called SPTT (Single Point Turning Tool). | Milling process utilizes a multi-point cutting tool, called milling cutter. |

| In turning, cutting tool continuously remains in contact with workpiece during the operation. | In milling, tooth continuously engages and disengages during operation (intermittent cutting). |

| Here the workpiece is rotated at fixed revolution per minute (RPM). This rotation provides necessary cutting velocity. | Here the cutter is rotated at fixed revolution per minute (RPM). Rotating cutter provides necessary cutting velocity. |

| In turning, feed motion is derived by moving the cutting tool (tool carriage). | In milling, feed motion is derived by moving the workpiece (worktable). |

| It can produce fragmented, discontinuous, or continuous chips (based on work and tool materials, cutting parameters, etc.). | Milling inherently produces discontinuous chips. |