Cutting Tool or Cutter is a wedge shaped device that compresses the workpiece material during machining to gradually remove excess material by shearing in order to obtain desired shape, size and accuracy. Geometry, orientation and material are three important factors that influence performance of a cutting tool in accomplishing material removal. Every conventional machining operation employs a physical cutting tool. Although basic shape and feature of such cutting tool vary greatly with the type of operation it is intended to perform, every cutting tool mandatorily possesses a wedge shaped portion with a sharp cutting edge, which can assist shearing and thus cut material smoothly and efficiently.

A particular cutting tool may contain one or more main cutting edges, and accordingly, it can be classified into three categories—single point, double point and multi-point cutting tools. As the name suggests, a single point cutting tool contains only one main cutting edge, a double point cutting tool contains two cutting edges, while multi-point cutting tool contains more than two main cutting edges. Number of cutting edges present in a particular cutter plays vital role in several aspects including chip load, material removal rate, cutting force, cost, etc. Important similarities and differences between single point and multi point cutting tools are discussed in the following sections.

Note: Metal cutting drill is the only example of double point cutter (few micro-end milling cutters may also contain two cutting edges). Thus, sometime cutters are classified only in two groups (single point and multi-point). So double-point cutters are also considered as multi-point cutters. This is primarily owing to the fact that drill may not necessarily have two cutting edges. For example, wood cutting drills typically have 3 or 4 flutes. However, for the sake of difference between single point and multi point cutters, double point cutter is not considered separately in this context; instead, it is subsumed into multi-point cutter group.

Similarities between single point and multi point cutting tool

- Both single point and multi-point cutters follows same principal for material removal (i.e. compressing a thin layer of workpiece material to gradually shear it off in the form of chips).

- Both are readily employed in conventional machining operations; however, a particular machining process utilize a particular type of cutter.

- Both types of cutter mandatorily contain sharp cutting edge; however, the number of cutting edges is different. In fact, this is the primary objective of classification of cutters as single and multi-point.

- Geometry and material are influencing factors for both types of cutter.

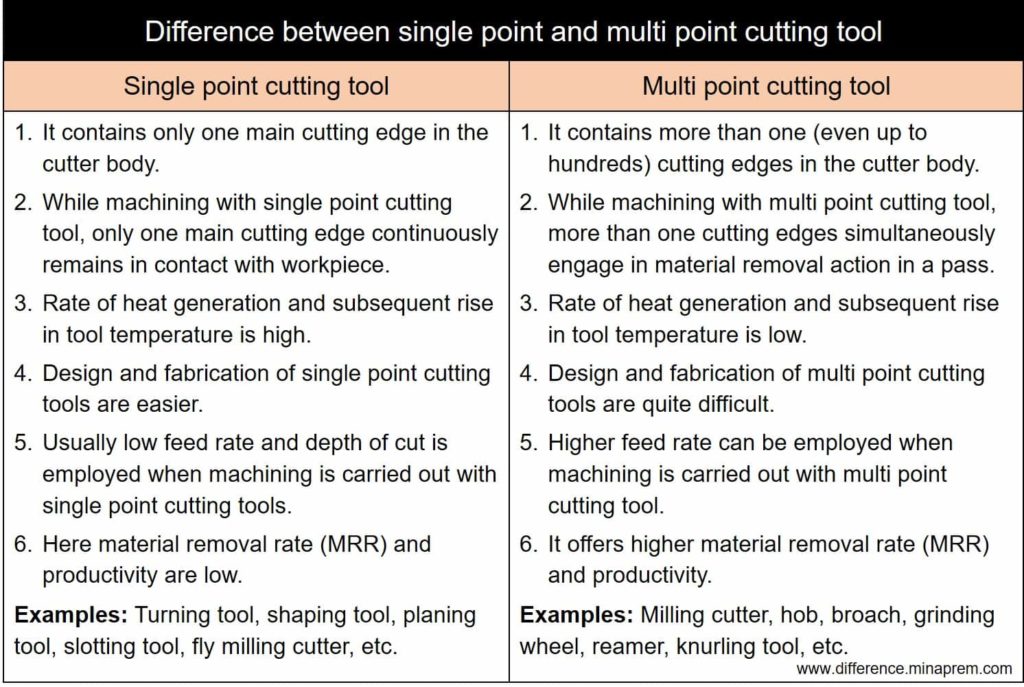

Differences between single point and multi point cutting tool

| Single Point Cutting Tool | Multi Point Cutting Tool |

|---|---|

| Single point cutting tools contain only one main cutting edge in the cutter body. | Multi point cutting tools contain more than one (even up to hundreds) cutting edges in the cutter body. |

| While machining with single point cutting tool, only one main cutting edge continuously remains in contact with workpiece. | While machining with multi point cutting tool, more than one cutting edges simultaneously engage in material removal action in a pass. |

| Chip load per tooth is usually high. | Due to presence of multiple cutting edges, effective chip load per tooth reduces. |

| Since one cutting edge continuously remains in contact with the workpiece, so rate of heat generation and subsequent rise in tool temperature is high. | Due to successive engagement and disengagement, heat dissipates from the cutter when it is not in contact with workpiece. Consequently rate of rise in tool temperature is low. |

| In case of unplanned breakage of cutting edge, entire process is required to pause until the broken tool is replaced by a new one. | If one cutting edge breaks, cutting action can be continued using other cutting edges without much problem. |

| Design and fabrication of single point cutting tools are easier. | Design and fabrication of multi point cutting tools are quite difficult. |

| Usually low feed rate and depth of cut is employed when machining is carried out with single point cutting tools. Accordingly, material removal rate (MRR) and productivity are low. | Higher feed rate can be employed when machining is carried out with multi point cutting tool. This increases MRR and productivity. Accordingly, machining operation becomes economic. |

Examples of single point cutters:

|

Examples of multi-point cutters:

|

References

- Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Saha et al. (2020); An analytical approach to assess the variation of lubricant supply to the cutting tool during MQL assisted high speed micromilling; Journal of Materials Processing Technology. https://doi.org/10.1016/j.jmatprotec.2020.116783

- Saha et al. (2020); An investigation on the top burr formation during Minimum Quantity Lubrication (MQL) assisted micromilling of copper; Materials Today: Proceedings; https://doi.org/10.1016/j.matpr.2020.02.379